From Invisible Data to Tangible Profit: Six Ways AI Optimizes Fleet Management

August 21, 2025 10 min read

AI fleet management technologies, which transform raw telemetry data into real-time, prescriptive hands-on assistance, are now used by fleets to keep wheels turning—and revenues growing. From route planning to tire pressure checks, they enable fleets to handle everything. They can even recognize the two-degree shift that signals a breakdown is imminent or detect a brief phone glance that signals fatigue. In addition to lowering fuel waste and unscheduled downtime, fleets that use AI management solutions are also finding efficiencies in real time. But most significantly, they are enhancing safety for their drivers, cargo, and other road users through real-time coaching. Keep reading to learn even more about how organizations can leverage AI to improve fleet performance.

From Raw Telematics to Prescriptive Intelligence

Modern trucks are moving data centers. One long-haul tractor during a ten-hour shift could generate over 30 million datapoints—location, engine temps, fuel flow, harsh-braking flags, camera images, tire pressures, and more. But a 2024 survey by Frost & Sullivan found that 90% of fleets use less than 5% of the data collected by their telematics boxes. For most fleets, dashboard analytics only include “Where’s my vehicle?”.

Artificial intelligence changes the game because it takes those streams of raw numbers and provides step-by-step directions. Instead of just warning that engine coolant temperature was too high, an AI model compares that number against weather, load weight, and repair records, then recommends throttling the truck down by 10% and scheduling a thermostat swap at the next depot. Instead of showing dots creeping across a map, the system provides dispatchers with prioritized tasks: refuel here to avoid surge pricing; reroute there to avoid a low bridge; and coach this driver to a smoother acceleration.

The net effect is prescriptive intelligence: actionable recommendations while the wheels are still turning, not a mountain of data sitting in a queue waiting for someone to sort through it after they are done driving.

Invisible Maintenance: Predicting Component-Level Failures Once Deemed Unpredictable

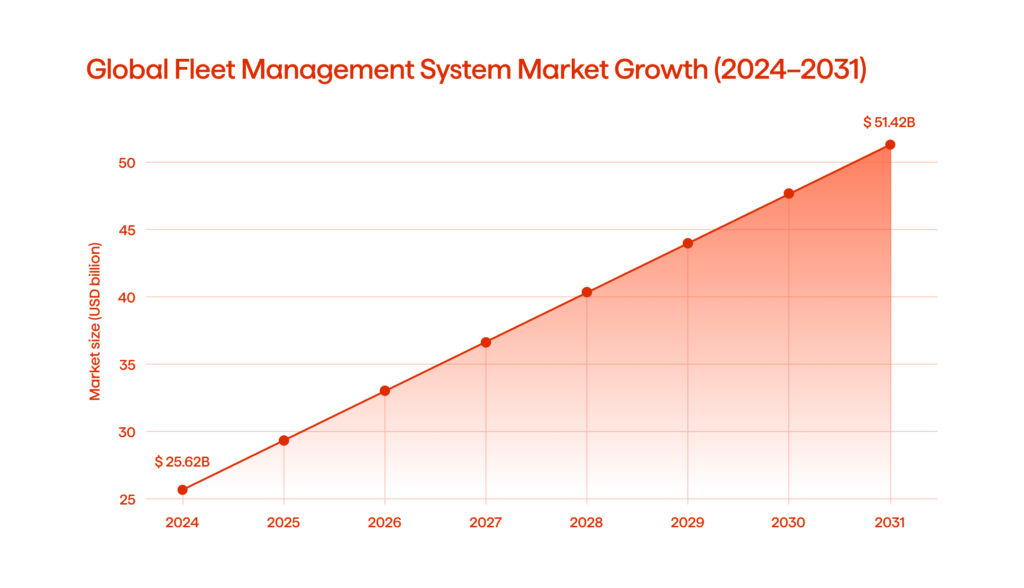

The market for fleet management is on fire, with estimates to grow from $25.62 billion in 2024 to $51.42 billion by 2031 — an annualized growth rate of about 10%. That line on the graph is not just a nice metric, it’s a spending forecast. It shows where fleet owners think their money will have the biggest return. A significant percentage of that incremental money is being allocated toward AI layers that account for more than dots-on-a-map, and more to true, deep, component-level intelligence—because uptime will always save more than the mileage report does.

Ask any fleet manager what concerns them, and “unexpected breakdowns” will be near the top of their list. Traditionally, PM schedules replaced parts based on mileage or hours accumulated. AI can learn the more subtle indicators of failure that may slip through telematics’ raw assessments. For example, an increase in injector pulse width, a slightly decreased air-compressor efficiency, or an odd two-degree rise in turbo outlet temperature—each is just noise in a vacuum, but collectively, a clock ticking towards a breakdown.

Modern predictive-maintenance platforms send these micro-signals through algorithms trained with millions of historical repairs using machine learning. When an algorithm indicates a likely NOx-sensor is about to fail, it doesn’t just bring a red light to the driver’s attention; it can calculate remaining service hours, order the part to cover the truck’s route, and reschedule the load—now the driver can keep their delivery promise. United Road’s car-hauler fleet used Uptake to do just that, replacing a $450 sensor at a convenient time rather than a $4,000 roadside bill.

The outcome is silent uptime, no more on-shoulder incidents, smaller spare-parts inventories, and mechanics that can fix the root cause of the problem instead of hunting fault codes. That is why the market is doubling; fleets are now betting a portion of their profit that AI will provide them “invisible” maintenance, with the next seven-year growth curve being transformed into tangible profits and not billable data costs, and so on.

Find out how we can help you implement predictive analytics for better, automated decision-making in your logistics business.

Dynamic Route Recalibration: Optimizing Beyond Traffic and Distance

Most fleet route-planning systems still rely on a rudimentary formula: shortest distance + least traffic = best route. But in today’s operating environment, that line of reasoning is inadequate. AI-powered routing doesn’t just optimize based on traffic congestion and mileage; it dynamically optimizes in real time, under your fleet’s unique business conditions. It considers dozens of different factors, including: road grade, the weight of the vehicle or freight, fuel economy, live weather updates, live availability of charging stations, and hours-of-service limits.

Picture this: a fully loaded EV box truck is on the way to its destination, but headwinds and elevation are about to push the vehicle just past its current battery range. Meanwhile, a diesel vehicle scheduled in the same area could perform the task more efficiently. The AI models know the limitations of both vehicles before they become an issue, will reshuffle routes, and relay the most competitive charging or refueling stations based on energy prices and wait times.

This helps achieve fleet efficiency. AI cuts down on fuel consumption, wait times for deliveries, and decreases driver fatigue, taking into account real-time road conditions and driver behavior, and recommending rest breaks — AI no longer relies on pre-set break schedules. McKinsey & Company observed that AI-powered routing can lead to operating costs that are 10% to 15% lower. This is not only fuel expense savings, but savings associated with less wear-and-tear on vehicles, better driver utilization habits, and lower chances for compliance violations. Dynamic routing will help reduce empty miles, eliminate delays in the sequence of stops, and facilitate optimal deliveries, even when the real-time driving conditions are anything but optimal.

AI also improved key aspects of an optimized route by presenting micro-adjustments between point A and point B. If there is an accident that shuts down a key stretch of interstate, if a storm hits an urban context, or if a loading dock goes offline, AI does not abandon an optimization route, but capitalizes on above-compliant re-routing—all while balancing compliance, cost, and efficiency. The outcome is not getting there, but getting there better each time.

Fuel and Energy Orchestration for Mixed Fleets

With traditional diesel or gas-powered assets alongside electric vehicles, fleets are transitioning from a focus on fueling to managing energy smartly across a mixed fleet. AI is becoming essential to this transformation, balancing fuel use, battery range, charging schedules, and energy costs to maximize overall fleet performance.

For example, with combustion engines, AI taps into its own data on topography, cargo weight, weather, and driver habits to calculate fuel burn, recommending alternative options when possible to have the fleet operate more efficiently—like rerouting to flatter terrain or rescheduling delivery routes to avoid live periods of heavy inner-city traffic. In contrast, AI uses real-time data and the same variables while evaluating EVs, such as if the battery range was exhausted due to strong stop/go traffic, headwinds, or inclines.

What makes AI tools uniquely powerful is their ability to manage both fuel and electricity use in the whole fleet. AI can manage which vehicles are assigned to which roads—EVs can be given preference for shorter and inner-city deliveries, with diesel vehicles receiving the long-haul assignments. AI systems will not only auto-schedule vehicle charging when costs are low, whenever possible in off-peak periods, but also account for local charging infrastructure availability and wait times before assigning routes to vehicles.

Driver Safety and Coaching Reimagined

The NHTSA estimates that more than 90% of all accidents on the roadway are linked to human error, and AI is now the in-cab co-pilot that fleets have not realized they needed for years. Vision systems now read eyelid droop, phone glances, and lane drift in real-time, while the telematic system flags harsh braking or cornering in the second that it happens. Rather than sending a general month-end safety email to drivers and management weeks after the unsafe behaviour has ceased, fleets can provide personalized tips within minutes of the unsafe behaviour when it is fresh in the driver’s memory.

Some examples of what AI-assisted coaching looks like in practice:

- Live feedback. A chime when the driver’s eyes are off the road for more than two seconds to prevent distraction before it falls into something dangerous.

- Post-trip highlights. A short video clip and scorecard are sent to the driver’s app, flagging smooth accelerations or risky merges caught on video during the day.

- Adaptive goals. The performance of each driver is compared to their driving history so that seasoned veteran drivers are not held to the standards of a rookie driver, and the other way around.

- Gamified leaderboards. A weekly ranking for the safest miles with fuel bonus incentives that turn safety into friendly competition rather than a lecture.

But early adopters have seen double-digit reductions in preventable crashes and corresponding insurance claims, and higher driver satisfaction, because driver feedback is timely, fair, and actionable. In other words, AI changes transport safety from a punitive checklist into an ongoing dialogue that leaves both drivers and cargo heading home safely.

Smart Compliance and Automated Paperwork

Hours-of-Service logs, DVIR walk-arounds, IFTA fuel taxes, bills of lading—the alphabet soup of fleet paperwork meant clipboards and late-night data entry. Every bit of it is now almost an ignored background task thanks to AI solutions. Newer ELD platforms like Motive (once KeepTruckin) and Samsara now couple sensor data with on-device OCR: a driver snaps a picture of a fuel receipt, and the ELD reads the gallons, checks telematics location, and autonomously posts the line item to an IFTA ledger.

Daily Vehicle Inspection Reports are now doing the same thing. Geotab Drive’s DVIR AI finds missing photos, flags contradictory notes, and even estimates repair time from image recognition of a tire tread or brake-pad wear. The driver completes the inspection as a voice note, and a clean PDF goes to maintenance, tagged for the correct asset.

On the freight side, applications like Vector eBOL and Transflo Mobile+ utilize natural language processing (NLP) to extract consignee names, seal numbers, and accessorial codes from scanned documents, then push a structured data entry into the TMS and bill queue. With Platform Science Workflow or Trimble Dispatch Advisor, you will be able to predict HOS violations hours in advance; the system will either reroute or swap trailers before the driver is ever in a position to be non-compliant.

What’s Next? Turning Unseen Data into Visible Profit

AI is no longer just a buzzword; it is already delivering bottom-line results. Fleets that deploy data pipelines along with AI-enabled fleet management can pilot narrow initiatives, develop deliberate scale management solutions, and accrue compounding wins; engines last longer, routes use fewer miles, audits close quicker, and they have fewer accidents. In a market expected to double by 2031, laggards will find themselves still chasing spreadsheets while market leaders will utilize AI to streamline energy consumption, capacity, and compliance. Leaders can’t afford to sleep on these gains as AI never sleeps. It is a straightforward pathway forward: clean data, pain points, leverage AI capabilities, then iterate.

Contact Avenga to discover even more about AI-powered fleet management software and how to utilize it in 2025 and beyond.